About Us

44 YEARS OF EXPERIENCE EXCELLENCE

Discover What ASCo Can Do for You: Expertise in Industrial Coating and Restoration

A DIVERSIFIED COMPANY PERFORMING COMMERCIAL AND RESIDENTIAL COATING REMOVAL AND APPLICATION

ASCo, American Stripping Company of Manassas is a diversified company that has been in business in Northern Virginia since 1980 performing blast cleaning, media blasting, powder coating and specialty painting services. With more than 44 years of experience and a talented work team ASCo Manassas has a successful history for completing many Industrial coatings projects, Historical cast iron restoration, art sculpture conservation and large commercial powder coating projects.

We are known best for our regional services, that require metallizing, zinc, epoxy and polyurethane painted finishes or powder coating. We apply powder coating using batch ovens and electrostatic powder guns as well as conventional air spray, electrostatic painting and large airless paint pumps.

Our 48,000 square foot facility in Manassas Park Virginia has the capacity for large and small projects. Indoor operations provide the ability for year-round production that is not limited by weather.

Our Team

At ASCo, our team is composed of skilled professionals who are dedicated to delivering high-quality services. With decades of experience and a commitment to excellence, our team ensures every project is completed to the highest standards.

JAMES SEJD

Co-founder and President

JIMMY PEREZ

Office Manager

MICHELLE

Customer Service

OLIVIA

Customer Service

OUR SERVICES

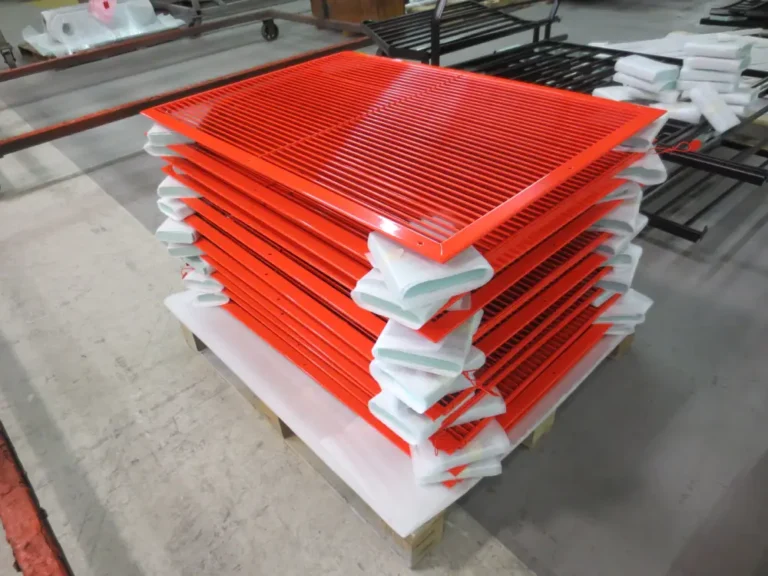

We protect metal with durable powder coating

Powder coatings are often used to protect steel and aluminum surfaces. Examples include: Powder Pipe Coating, Powder Steel Coating, Duct Work, Powder Coating Motorcycle Frames, Metal Coating, Military Parts, Powder Coating Frames, and Industrial Parts.

Powder offers a fast and efficient means of protecting steel and aluminum surfaces while remaining competitively priced and environmentally friendly.

Our Capabilities

American Stripping Company is a diversified company with the ability to perform work at the customer’s project site or in our shop under any weather capabilities.

We have NACE and SSPC trained staff, a full complement of test equipment and QUV test chambers to confirm manufactures test data.

Our trained crews have successfully completed field projects which have included work around the globe and here at home. ASCo has a significant inventory of air compressors, blast pots and related blasting equipment for immediate mobilization. Projects can be performed more cost efficiently or restricted by weather constraints are blast prepared and coated in our 48,000 sq/ft Manassas facility.

Our 44 years in business has allowed us the opportunity to provide services to many diverse industries with excellent results. We have large work areas both indoors and out for project mock ups and pre-assemblies when required.

- 48,000 sq/ft indoor workspace

- 40,000 sq/ft outdoor workspace

- Electrostatic powder coating and fluidize bed coating

- Ovens (2) @ 9’ x 9’ x 24’

- Powder inventory 350 + stock colors

- (4) manual electrostatic powder coating guns

- 14’ x 14’ x 40’

- 12’ x 8’ x 25’

- Paint mixing room

- Electrostatic paint guns

- Air assisted airless

- HVLP air spray

- Conventional air spray

- Airless paint equipment.

- Blast Booths 16” x 14” x 40’

- Blast Booth 12” x 14” x 25’

- 100,000 lbs + abrasives in stock

- Black slag

- Garnet

- Soda blast

- Walnut shell

- Glass bead

- Steel shot

- Plastic media

- Sponge blast

- (5) 6,000 lbs forklifts

- (1) 8,000 lbs forklift

- (1) 40’ JLG

- (1) 18’ scissor lift

- (1) 2,000 lbs bridge crane

- (2) CDL Trucks

- Key employees have OSHA 10 hour & 30 hour certified course

- Fire rated flammable storage

- OSHA inspection July 2023 / passed

- 350 hp/ 1,155 CFM shop compress air

- 1,000 CFM portable and suplimental compressed air

Thermal arc spray guns TAFA / PRAXAIR and Miller

- MIG / TIG / Gas / Stick welding equipment

- ( 2 ) Certified welders

LOCATION

Electrostatic/ Fluidized Bed Powder Coat

MIG/TIG/Gas/Stick Welding Equipment

- 2 Curing Ovens 7′ x 8′ x 20′

- 2 Powder Ovens 7′ x 8′ x 20′

- 1 Paint Booth 14′ x 40′ x 14′

- 1 Paint Booth 12′ x 25′ x 8′

- 1 Paint Mixing Room

- Conventional/ Electrostatic/ Airless Paint Equipment

- 2 Blast Booths 16′ x 40′ x 14′

- 1 Blast Booth 14′ x 25′ x 12′

- 100,000 + lbs Abrasive in stock

- 58,000 sq/ft Total Indoor Space

- 40,000 sq/ft Lay Down Yard

- 28 Employees

- 6 Forklifts

- 2 CDL Trucks Flatbed/Box

- 5 Pickup Trucks

- 3 Contractor Trailers

- 24,000 lbs Lifting Capacity Single lift

- 2,000 lbs Bridge Crane Capacity

- Approved Fire Rated Flammable Storage

- July 2015/Passed OSHA Inspection

- 350 HP/1,155 CFM Shop Compressed Air

- 1,000 CFM Supplemental Compressed Air

- 4 Thermal Spray Equipment TAFA and Miller